Introduction: Packaging That Sells and Protects

In the age of first impressions and hyper-branding, packaging is no longer a secondary concern — it’s the first point of customer engagement. Whether your product is stacked on retail shelves or shipped across the country, its packaging needs to perform two vital functions:

✅ Look Good

✅ Last Long

This is where printed laminated bags shine. They combine visual brilliance with structural durability, offering brands a way to showcase their identity while preserving product integrity.

🛍️ Think of them as the perfect marriage between aesthetic appeal and functional performance.

What Are Printed Laminated Bags?

Printed laminated bags are multi-layered flexible pouches made by bonding different materials — typically plastic films like PET, BOPP, PE, or aluminum foil — with adhesives. The outermost layer is printed with high-resolution graphics, branding, or essential product information.

📦 Components of a Laminated Bag:

- Outer layer: For print and surface finish (e.g., gloss, matte)

- Middle layer: Acts as a barrier against moisture, oxygen, or UV rays

- Inner layer: Provides heat sealing and direct product contact safety

Lamination allows for vibrant, fade-resistant printing, while the layered structure adds strength, puncture resistance, and product protection.

🎯 Perfect for FMCG, cosmetics, agro, food, and chemical sectors that demand both performance and shelf appeal.

Key Benefits of Using Laminated Bags for Packaging

Laminated bags are quickly becoming the go-to solution for businesses aiming for quality, efficiency, and style. Here’s why:

- 🎨 Superior Branding and Visual Appeal

- Full-color, edge-to-edge printing

- Metallic, matte, or textured finishes

- Support for QR codes, barcodes, and regulatory info

- Retains vibrancy over time and handling

- 🛡️ Enhanced Barrier Properties

- Keeps out moisture, oxygen, dust, and UV rays

- Extends product shelf life significantly

- Ideal for products sensitive to air or light

- 📦 Structural Durability

- Puncture and tear-resistant

- Holds shape and doesn’t collapse like basic plastic

- Withstands stacking, transport, and rough handling

- 🔄 Versatile Usage Across Industries

- Food (snacks, grains, spices)

- Cosmetic (creams, powders, refill kits)

- Pharma (sachets, wipes, disinfectants)

- Industrial (powder coatings, hardware)

- Agriculture (fertilizers, seeds, animal feed)

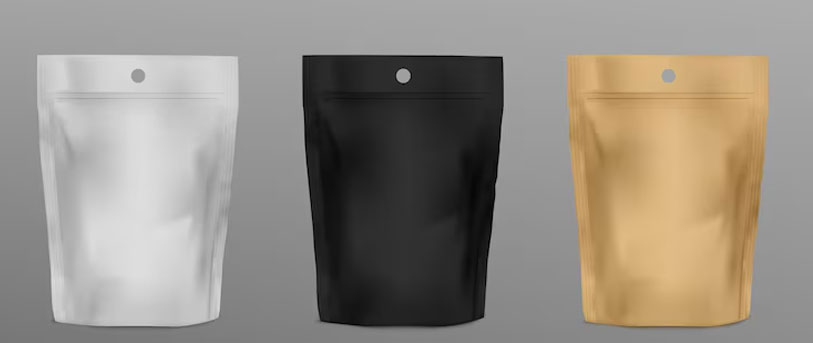

- 🧩 Custom Formats and Closures

- Zipper, spout, valve, tear notch, Euro slot

- Available in stand-up, flat, gusseted, or quad seal formats

💡 One bag, endless possibilities — laminated bags are your canvas for storytelling and product protection.

Why Printed Laminates Are the Gold Standard Today

The global shift toward sustainable, compact, and premium packaging has made laminated bags the preferred format for both small businesses and large manufacturers. Why?

- ✅ Lightweight, reducing shipping costs

- ✅ Occupy less space in transit and storage

- ✅ Recyclable options now widely available

- ✅ Compatible with automated filling and sealing lines

- ✅ Consumer-friendly with resealability and tear control

Moreover, lamination extends print life and prevents smudging or color bleed — which is crucial in hot, humid, or export-heavy environments.

🌎 From factory to customer, laminated bags ensure your brand stays protected and presented just as you intended.

Applications of Printed Laminated Bags Across Industries

Printed laminated bags are used in nearly every product category that demands attractive design + high barrier performance. Here’s how various sectors benefit:

🥗 Food & Snacks:

- Chips, namkeen, dry fruits, cereals, frozen foods

- Keeps flavor locked in, resists grease and oxygen

🧴 Cosmetics & Personal Care:

- Face masks, wet wipes, body scrubs, herbal powders

- Prevents moisture ingress, protects delicate contents

💊 Pharma & Healthcare:

- Disposable sachets, medical kits, sanitizing wipes

- Ensures sterility, product lifespan, and tamper evidence

🧪 Chemicals & Agro:

- Pesticides, fertilizers, desiccants, granules

- Requires strong puncture resistance and leak-proofing

🧰 Hardware & Industrial:

- Screws, fittings, tools, adhesives

- Tough bags that hold shape and weight without bursting

🧠 Whatever you pack — laminated bags keep it safe, secure, and sharp-looking.

Choosing the Right Laminate Structure for Your Product

Not all products need the same level of barrier protection. That’s why laminated bags come in custom material structures, based on what’s being packed.

Common Material Combinations:

| Layer | Function | Common Combinations |

|---|---|---|

| Outer | Printable layer | PET, BOPP |

| Middle | Barrier layer | MET PET, Foil |

| Inner | Sealable contact | PE, CPP |

Based on Usage:

- Moisture-sensitive items → PET / MET PET / PE

- High-aroma products → PET / Foil / PE

- Heavy powders or granules → BOPP / PE or Nylon reinforced

Crystal Containers helps you choose the optimal laminate structure for performance, compliance, and cost-efficiency.

How Printed Laminates Improve Shelf Presence and Branding

A great product deserves packaging that stands out. Printed laminates allow for bold design, color fidelity, and lasting impact.

Branding Advantages:

- Edge-to-edge printing for a premium look

- High-resolution graphics with no peeling or fading

- Matt/gloss combination effects for tactile branding

- Metallic or soft-touch finishes for visual appeal

- Transparent windows for product visibility

Whether you’re showcasing a food item or a luxury cosmetic — packaging is your silent salesperson.

🛍️ The difference between being picked or skipped on the shelf often comes down to the bag design.

Crystal Containers’ Customization Capabilities

We don’t offer generic pouches — we create custom-fit solutions for your product, brand, and usage.

📐 Custom Shapes:

- Stand-up pouch, pillow pouch, quad seal, bottom gusset, spout pouch

- Unique die-cut shapes for category distinction

🎨 Print Techniques:

- Rotogravure (up to 9 colors) for sharp, repeatable printing

- Flexographic printing for volume runs

- Digital printing for short, quick turnaround runs

🌟 Surface Finishes:

- Gloss, matte, soft-touch, metallic, embossing

- Anti-scuff and anti-scratch coatings

🔖 Closures:

- Zippers, tear notches, Euro holes, valve vents, spouts

You imagine it, we prototype it. That’s how custom gets done at Crystal Containers.

MOQ, Print Options, and Sustainability Features

We believe great packaging should be available to brands of all sizes. That’s why we offer:

✅ Low MOQs:

- Start as low as 3,000 pieces for standard pouches

- 5,000–10,000 for custom formats or premium finishes

✅ Multiple Print Options:

- Support for small batch launches

- Reorders made easy with stored designs and color codes

✅ Eco-Friendly Materials:

- Mono-material recyclable laminates

- Bio-based laminates on request

- Water-based inks for select applications

🌱 Beautiful packaging shouldn’t come at the cost of the planet.

Why Leading Brands Prefer Our Laminated Packaging

Here’s what sets Crystal Containers apart as a top laminated pouch manufacturer:

✅ In-House Printing & Lamination – Quicker delivery, better control

✅ Full Compliance – Food-grade, export-ready, REACH & ROHS compatible

✅ End-to-End Support – From sampling to scale-up

✅ Export-Capable – Packaging ready for global retail

✅ Pan-India Reach – Serving brands, wholesalers, and OEMs

💬 Your product is premium — let the packaging reflect that.

🟩 Who Should Use Printed Laminated Bags?

If your product requires a combination of branding visibility, protective strength, and flexible handling, printed laminated bags are ideal.

Best-suited for:

- D2C brands needing premium unboxing appeal

- Exporters wanting long shelf-life & barrier packaging

- Retail food brands focused on aroma retention & leak-proof sealing

- Cosmetic brands seeking premium surface finishes

- Agro or pharma companies needing high puncture resistance

- Private label manufacturers requiring batch traceability

🧪 From everyday groceries to high-end skincare — laminated bags deliver form and function in one solution.

Tips to Select the Right Laminated Packaging for Your Product

Choosing the right structure depends on:

- Product Nature: Dry, wet, aromatic, powder, or sensitive

- Shelf Life: Short-term vs. long-term protection

- Closure Needs: Reusable zip, tear notch, spout

- Print Complexity: Gradient colors, foil stamping, embossing

- Branding Goals: Minimalist matte vs. bold metallic appeal

🎯 The right packaging elevates your product, reduces damage, and creates lasting brand recall.

Our team assists you with:

- Laminate selection

- Pouch design & layout

- Regulatory label integration

- Mockup sampling & trials

Certifications, Testing & Compliance Standards

Crystal Containers follows strict QA norms to ensure your laminated bags meet global and domestic packaging standards.

We offer:

- ✅ ISO 9001:2015 certified production

- ✅ Food-grade, BPA-free laminates

- ✅ Ink migration & seal strength tests

- ✅ REACH, ROHS, and FDA-compliant options

- ✅ Batch-wise QC reports on request

- ✅ Export support with HS code, CoO, MSDS

🧾 We don’t just supply pouches — we supply trust, certified.

Why Choose Crystal Containers for Laminated Packaging

We are one of India’s trusted partners for custom-printed laminated pouches across B2B segments.

Here’s why clients choose us:

- 🖨️ In-house design, printing, and lamination = faster turnarounds

- 📦 Flexible MOQ = scale as per your need

- 🌎 Serving 200+ clients across India and overseas

- 🛠️ Rapid prototyping and sampling

- 🔁 Easy reorder and inventory management

From startups to large OEMs, we provide personalized attention and scalable capacity.

📩 Need a printed laminated bag sample? Contact Us Now

15 Voice Search–Optimized Buyer FAQs

- What are printed laminated bags used for?

They’re used for food, cosmetics, chemicals, hardware, and retail packaging with branding.

- Are laminated bags waterproof?

Yes, they provide excellent barrier against moisture and air.

- Can I print my brand on the bag?

Absolutely. We offer full-color custom printing.

- What finishes are available?

Gloss, matte, metallic, soft-touch, and custom effects.

- Are these bags recyclable?

Yes, we offer recyclable and sustainable options.

- What is the minimum order quantity?

MOQ starts from 3,000–5,000 depending on specs.

- What is the delivery time?

Typically 7–15 working days after print approval.

- Can you make spouted or zip-lock pouches?

Yes, with full customization support.

- Do you ship across India?

Yes, and also support exports globally.

- What materials are used in laminates?

PET, BOPP, PE, Foil, MET PET, and more.

- Do you provide pouch samples?

Yes, pre-print samples and dummy pouches are available.

- Are your inks food-safe?

Yes, all printing is done with food-grade, non-toxic inks.

- Can you handle urgent orders?

Yes, express runs are possible depending on slot availability.

- What types of bags do you make?

Stand-up, pillow, quad seal, flat bottom, and more.

- How do I start an order?

Visit Contact Us or speak to our team today.